Achieving Superior Finishes with In-Mold Decorations in Production

Achieving Superior Finishes with In-Mold Decorations in Production

Blog Article

Mastering In-Mold Decorations: Approaches, Fads, and Ideal Practices for Optimal Outcomes

In the realm of manufacturing, the art of in-mold decorations stands as a pivotal aspect of item design and production. As sectors continually seek innovative ways to improve visual appeal and functionality, grasping the intricacies of in-mold decorations has become an essential capability. From choosing the ideal materials to integrating advanced design patterns, the trip in the direction of attaining optimal results in this domain name is complex. By delving right into the approaches, fads, and best techniques that underpin effective in-mold decoration processes, companies can open a world of opportunities that not only raise the aesthetic appeal of their products yet also streamline manufacturing efficiency and bolster customer involvement.

Material Choice

Material choice is an essential facet of grasping in-mold designs, as it straight influences the quality and toughness of the last product. When selecting materials for in-mold decorations, it is necessary to consider variables such as compatibility with the molding procedure, the preferred aesthetic outcome, and the ecological problems the item will encounter.

Moreover, the picked product needs to have good bond residential properties to guarantee that the decoration adheres strongly to the substrate during the molding procedure. Attachment in between the decoration and the material is vital for avoiding delamination and making certain lasting aesthetic appeal. Furthermore, products with high warmth resistance are preferred for in-mold designs, specifically for products that will be subjected to raised temperatures during their lifecycle. By very carefully choosing the proper material for in-mold designs, makers can boost the total quality and longevity of their products, meeting the assumptions of both customers and end-users.

Design Development

A vital consider advancing the field of in-mold decorations is the continuous exploration and execution of layout technology methods. Style development plays an important role in enhancing the aesthetic allure, performance, and overall quality of products made making use of in-mold design processes. By including cutting-edge style elements, suppliers can separate their products in the market, bring in customers, and stay in advance of competitors.

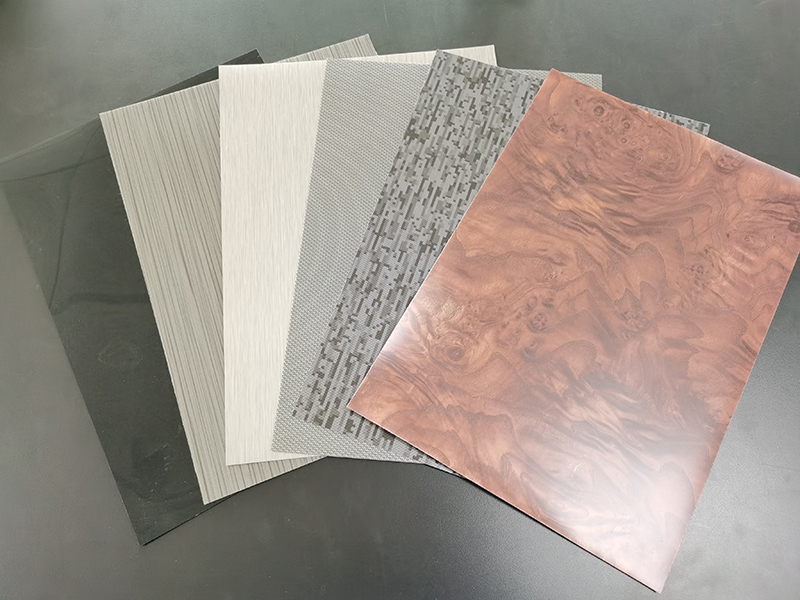

Among the essential elements of design development in in-mold decorations is the assimilation of detailed patterns, structures, and graphics that were previously testing to accomplish with conventional design methods. Advanced innovations such as 3D printing and digital design devices enable designers to create facility and comprehensive layouts that can be perfectly moved onto molded parts. Additionally, using vibrant shades, metallic surfaces, and unique results like gloss or matte structures can further raise the aesthetic appeal of in-mold embellished items.

Additionally, style innovation prolongs past visual appeals to incorporate functional enhancements such as ergonomic shapes, incorporated features, and adjustable components that cater to certain customer demands. By accepting layout innovation, producers can open brand-new opportunities for creative thinking, item, and personalization distinction in the affordable landscape of in-mold decors.

Manufacturing Efficiency

Reliable production processes are necessary for translating the cutting-edge styles established in the field of in-mold decors into high-grade finished products that fulfill market demands and customer assumptions. In the world of in-mold designs, manufacturing efficiency includes various vital elements that add to the overall success of the manufacturing procedure.

Automation not just speeds up the manufacturing process but likewise improves accuracy and repeatability, leading to an extra high-quality and consistent end product. On the whole, a holistic approach to manufacturing performance is vital in making best use of the potential of in-mold design methods and useful link achieving optimum outcomes in the competitive market landscape.

Quality Assurance Procedures

What are the crucial approaches for making certain rigid high quality control measures in the realm of in-mold decorations? Quality assurance procedures are vital in in-mold decoration procedures to make certain basics the manufacturing of remarkable and top quality finished items. One important method is the implementation of extensive inspection methods at every phase of the production procedure. This entails performing complete aesthetic examinations, dimensional checks, and color consistency analyses to recognize any kind of inconsistencies or defects at an early stage.

Making use of advanced innovations such as computerized evaluation systems can additionally enhance the quality assurance process by giving exact and trusted information for analysis. These systems can spot imperfections that might be missed out on by hand-operated evaluations, therefore improving total product top quality and uniformity.

Routine training and growth programs for employees entailed in the in-mold decor process can likewise add to keeping premium standards. By informing team on ideal practices, quality expectations, and the value of focus to information, companies can foster a culture of high quality consciousness throughout the organization.

Consumer Appeal

To boost the marketability of in-mold decor items, recognizing and catering to consumer choices play an important role in identifying their charm and success. Offering modification choices such as personalized layouts, color variants, and textural components can substantially enhance the charm of in-mold decoration items.

Conclusion

In-mold designs use a functional and efficient means to boost product aesthetics. By thoroughly choosing products, accepting ingenious designs, maximizing manufacturing procedures, implementing quality assurance steps, and prioritizing consumer allure, producers can achieve optimal outcomes. It is essential for business to constantly adapt and improve their methods to remain competitive on the market. In-Mold Decorations. Mastering in-mold decors needs an all natural strategy that takes into consideration all facets of the production process to guarantee success.

In the world of manufacturing, the art of in-mold decorations stands as a pivotal facet of product design and manufacturing. Style development plays a vital function in enhancing the visual charm, functionality, and total high quality of items produced making use of in-mold decor processes.One of the vital elements of design technology in in-mold designs is the integration of intricate patterns, appearances, and graphics that were previously testing to achieve with typical design approaches.Effective manufacturing procedures are necessary for translating the cutting-edge designs established in the area of in-mold designs right into premium finished items that meet market demands and customer expectations. Using customization alternatives such as customized layouts, color variants, and textural elements can substantially boost the charm of in-mold decor items.

Report this page